In a context where insect control, energy management, and grain quality preservation are major challenges for storage organizations, we invite you to discover Oxyane’s feedback.

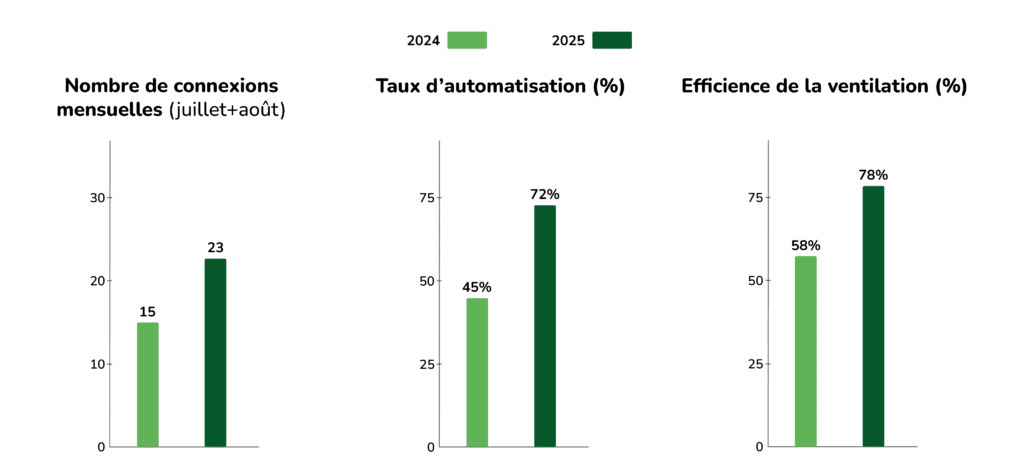

The cooperative explains how it managed to engage all its employees with the help of Javelot and achieve 78% ventilation efficiency on its 750,000 tonnes of grain, thanks in particular to the deployment of the Javelot solution and the strong commitment of its field teams.

From a Pilot to a Successful Industrial Deployment

After an initial phase equipping 300,000 tonnes between 2018 and 2020, Oxyane chose to extend the Javelot solution to all of its storage capacity in 2023, reaching a total of 750,000 tonnes deployed across a very diverse range of storage sites.

“Given our development strategy for value chains and the move away from insecticides, we were keen to bring coherence to the management of our stocks. Javelot has now scaled to a higher level and strengthened itself with knowledge and expertise,” explains Raphael Comte, Grain Division Director at Oxyane.

A Rise in Ventilation Efficiency from 58% to 78% Between 2024 and 2025

The chart below illustrates the increase in ventilation efficiency observed over one year, directly linked to the commitment of silo managers and the widespread adoption of automatic mode.

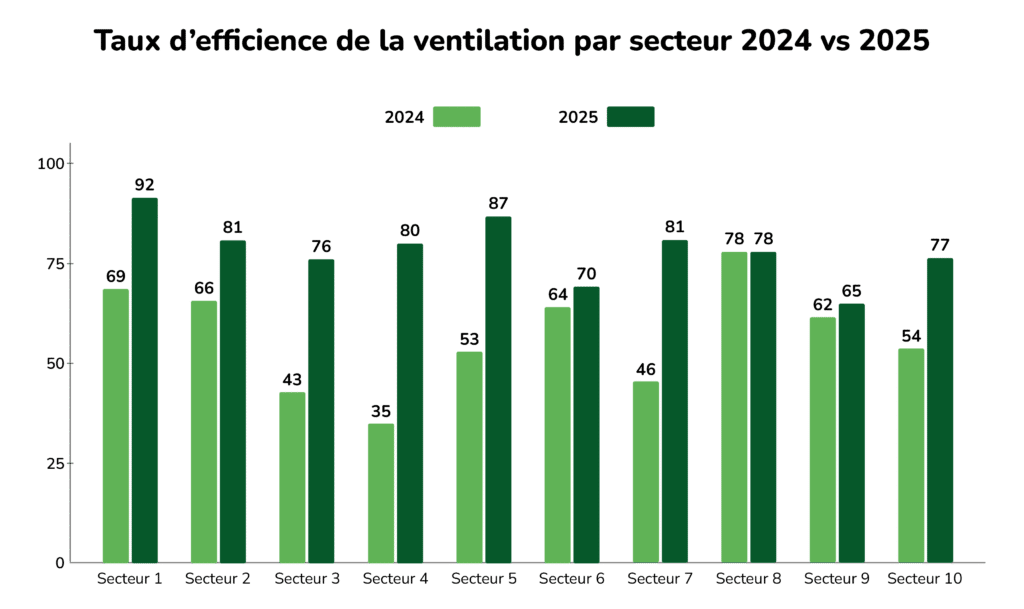

Driving Regional Team Performance

At Oxyane, Javelot has become a key management tool to drive operational performance. The platform makes it possible to monitor adoption and performance by sector, giving managers a clear view to lead their teams, understand where and why performance is strong, challenge sectors, highlight successes, and co-build concrete action plans to progress collectively.

A Project-Based Approach to Succeed in the Transformation

“Not everything has always been easy to reach this outcome,” recalls Raphael Comte. “We were among the first to work with Javelot, at a time when both the solution and the teams were still being structured. However, throughout the project, Javelot was able to listen, question itself, and adjust its support to ensure the success of large-scale deployment. On our side, we appointed a dedicated project manager to create a shared dynamic around performance objectives—both with silo managers and with maintenance or investment teams. Today, no one would want to go back from this technology.”

Raphael Comte, Grain Division Director at Oxyane